Case Study: Vertiv Pumped Refrigerant

about this project

Tier 5 Systems tackled the challenge of retrofitting traditional IT spaces into Hot Aisle Containment pods over five years, while ensuring all systems remained operational. The project involved innovatively overcoming discontinued accessories by recreating essential components and installing four 160kw Vertiv pumped refrigerant systems across six IT pods, achieving N+1 redundancy and minimizing refrigerant leak risks. This approach not only maintained the necessary cooling but also preserved valuable IT equipment space, demonstrating Tier 5's adaptability and technical proficiency in complex environments.

Case Study

The Challenge

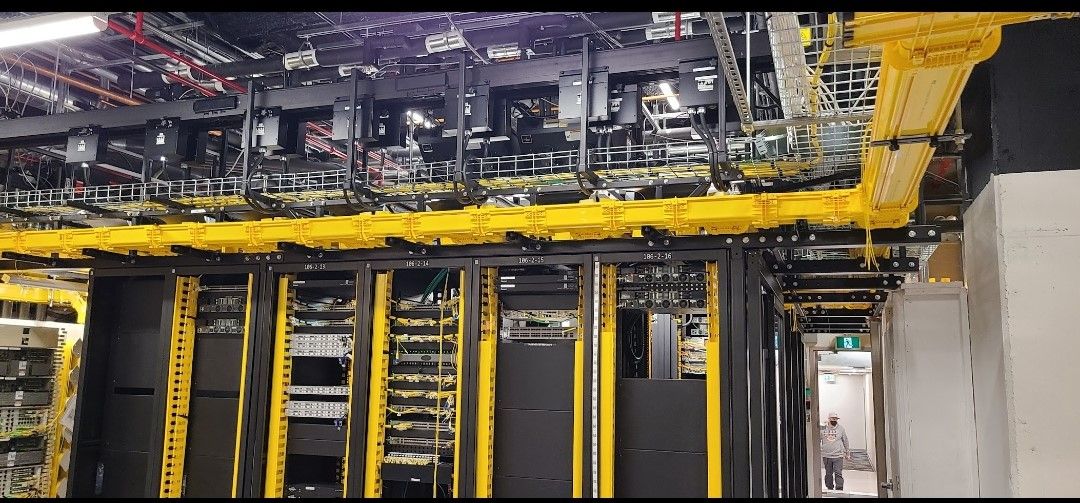

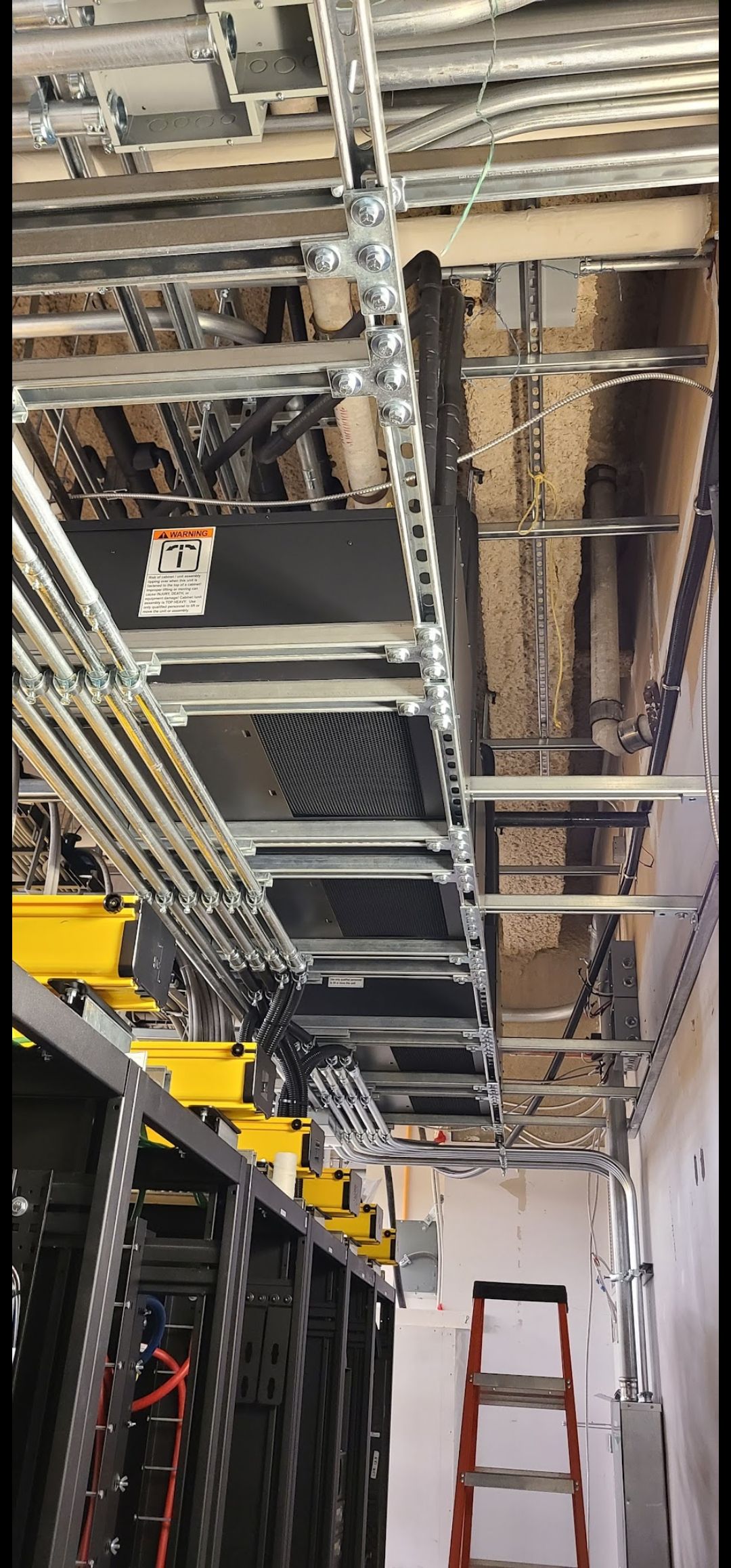

This project is a retrofit upgrade from traditional IT space to Hot Aisle Containment pods. The system was built over 5 years and is still ongoing. All systems needed to be operational and functioning during expansion. The manufacturer discontinued some of the accessories in the pumped refrigerant system. Tier 5 had to re create the manufacturers pumped refrigerant headers and delete installed flex hoses as they were a source of refrigerant leaks.

What We Did

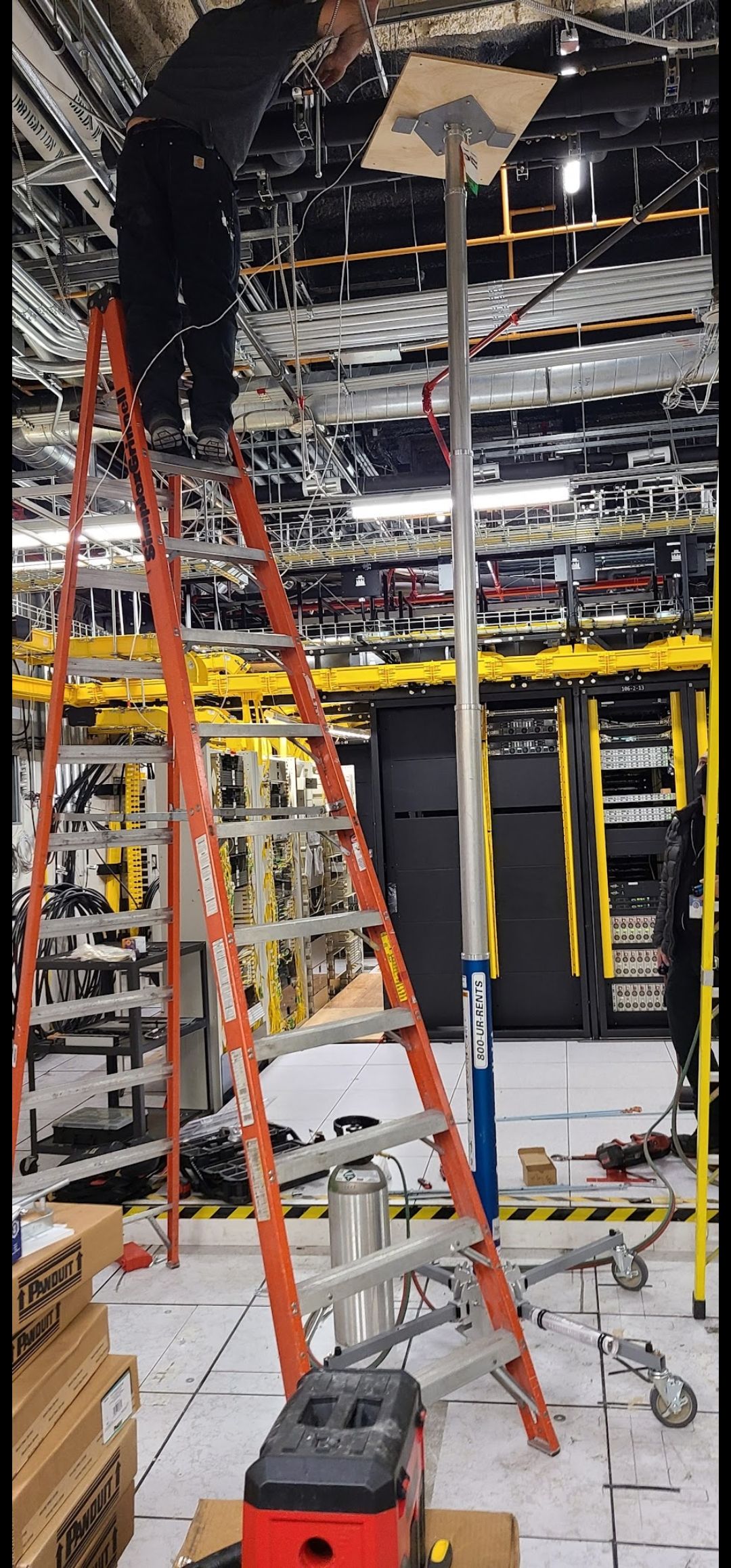

We installed four 160kw Vertiv pumped refrigerant systems with over head modules in 6 different IT pods. Each IT pod is serviced by 2 pumped refrigerant systems, interlacing the cooling modules to provide N+1 redundancy. Air cooled CRAC units also had to be moved around the data center as the retrofit progressed. These complicated tasks are achieved by careful planning and executing each stop of the MOP (method of procedure) and insuring each team member follows these steps.

What We Achieved

The implementation of the Vertiv pumped refrigerant system exceeded manufacturers recommended refrigerant line lengths. To mitigate the issue the installation was meticulously installed ensuring the correct slope back to the pumping unit was maintained throughout installation and changes in direction were kept to a minimum. This systems uses chilled water to sub cool large amounts of refrigerant that is then pumped to the data center. This system has two significant advantages where if a cooling leak accurse in the data center there is no risk to the electrical gear and that these cooling modules take up zero white space for IT equipment.

Read More Case Studies

Case Study:

Upgrading CRAC System

from R22 to CO2

Case Study:

Vertiv Pumped Refrigerant

Case Study:

DX In-Row Cooling

CONTACT US

All Rights Reserved | Tier 5 Systems